Making a Floor in the Traditional Chinese Way

木材料的营造技艺由来已久,古人植树造林,截木为材,盖房子、制家具,生活在树木旁,住在“木材里”,在木桌上吃饭、在木床上睡觉。那时候,人们虽然没有先进的工业机器,只有世代相传的传统手工工艺,却能建造出跨越千年依然保存完好的一些古老的木构建筑,这引起了我们对传统方法制作木头的关注。

The craft of making wood materials has a long history. Ancient people planted trees, felled them for timber, and used them to build houses and make furniture. They lived next to the trees and lived "among the wood", eating on wooden tables and sleeping on wooden beds. In those days, although people did not have advanced industrial machines, but only traditional handcrafts passed down from generation to generation, they were able to build some wooden structures that have remained intact for thousands of years, which draws our attention to this traditional method of making wood.

Traditional Chinese Woodworking

中国传统的木制产品从木材的选取到处理工艺都十分考究。例如中国最古老的木制乐器——古琴,制琴师通过倾听一棵树在打雷时产生的共振,判断这棵树是否可以作为制作古琴的良好材料,然后再经历制胚、髹漆、装配等数十道复杂的工艺流程,才能制成一把上好的古琴,足以保留上千年。又如与大漆手工艺人范建军合作[中国传统材料之木材料与大漆]研究过程中,我们了解到制作大漆木胎一般最好选用柏木。他在处理前会先观察木头,根据木导管纹路生长方向将木头沿树根部到梢部的方向顺纹处理(竹材的方向则与其相反),并且一块木板其实是有正反面的,在拼接过程中不仅要讲究尺寸比例,还要考虑正反面的应力分解。

Traditional Chinese wooden products are made with great care, from the selection of wood to the treatment process. For example, when the guqin, China's oldest wooden musical instrument, is being made, the luthier will listen to the resonance of a tree during a thunderstorm to determine whether the tree can be a good material for making the guqin. Then, after dozens of complex processes such as embryo making, lacquer painting and assembly, a good guqin can be made, and a well-made guqin is good enough to be kept for thousands of years.In addition, in the course of working with Fan Jianjun , a lacquer craftsman, on the project [The Lacquer of Traditional Chinese Handicrafts], we learned that it is generally best to use cypress wood for the embryo of lacquer woodwork. Fan Jianjun observes the wood before treating it, and according to the direction of growth of the wood's conduit , he treats the wood with the grain along the root to the tip of the tree (bamboo is treated in the opposite direction). Moreover, a board is actually has a positive and negative side, in the splicing process, not only to pay attention to the size and proportion, but also to consider its positive and negative sides, as well as the "stress cracking".

分析和处理木材的范建军

这个过程与现代工业技术的高效法则不同,它体现了“顺势而为”的造物理念以及对一棵树的尊重,于是我们开始思考:从一棵树开始,用中国传统的工艺方法重新诠释一块木地板的诞生过程。在范建军和成都木工艺人黄大拿的帮助下,我们对“如何用中国传统方法做一块地板”开始了深入的探索和记录。

This process is different from modern industrial technology, which is based on the law of efficiency, but it reflects the concept of making things by following the trend and respecting a tree. So we began to think that we could start with a tree and reinterpret the process of creating a wooden floor using traditional Chinese wood craftsmanship. With the help of Jianjun Fan and Chengdu carpenter Dana Huang , we began to explore and document " How to make a floor in the traditional Chinese way".

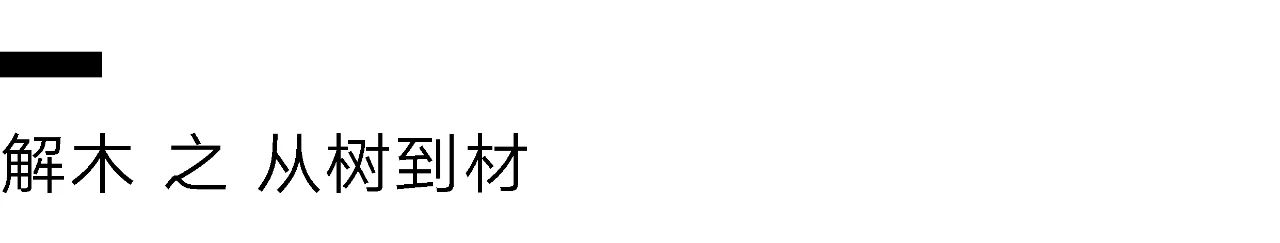

Wood treatment: From trees to timber

种

Planting

一块木地板的制作是从种树开始的。一棵栋梁之材从生长开始就会被进行干预,纬度、海拔、光照、水分、空气等都会影响它的生长。有意思的是,我们的古人往往砍伐的都是他们的祖辈种下去的树木,所以可能他们世代都是以木为生。

In the traditional Chinese method of making wood, a piece of wooden flooring begins with the planting of a tree. People intervene at the very beginning of a building block's growth, and latitude, altitude, light, and moisture all influence its growth. Interestingly, our ancient people tended to cut down trees that their grandparents had planted, so perhaps they lived on wood for generations.

松、杉、柏都是古代中国常用的木建筑材料,其中柏木装饰性强、质地坚韧,是制作地板的良好木材。当一棵柏树逐渐生长成材、具备了足够尺寸的木心时,便可以用来制作地板;只有少数比较粗壮的柏树可以取到足够尺寸的木心,制作成长900、宽95毫米的地板。

Pine, cedar and cypress were all commonly used wood building materials in ancient China, with cypress being decorative and tough, making it a good wood for flooring. When a cypress tree grows up and has a heartwood of sufficient size, it can be used to make flooring. Only a few of the more robust cypress trees have a core of sufficient size to make a floor 900 millimeters long and 95 millimeters wide.

伐

Felling

中国传统方法中,伐取树材非常讲究天时、遵循自然规律,认为冬天伐木优于夏天。此外,月亏时,树木体内循环的营养多汇聚于根部,这时采伐下来的树木不易腐烂、招虫,材质也会更好。

In the traditional Chinese method, the felling of trees is based on the time of the year and the laws of nature, and it is generally believed that felling trees in winter is better than in summer. In addition, at the waning moon, the nutrients circulating in the tree's body converge at the roots, and the trees cut down at this time are less susceptible to rotting, attracting insects, and the material will be better.

沤

Soaking

伐取下来的树需要经过初步的防腐处理。泡水便是一种古老的木材防腐处理方法,这个过程一般称为“沤树”:将树材整根投入水中,种类不同浸泡时长也有异。在水的浸泡下,树木中的营养成分以及虫卵被自然地去除,从而达到防虫、防腐的效果;同时,充足的水分滋养可以弱化树木纤维的咬合力,使其稳定性和抗变性更强。

Felled trees need to undergo a preliminary preservative treatment. Soaking in water is one of the oldest methods of wood preservation: The whole tree is put into the water, and different types of trees require different lengths of soaking. Under the soaking of water, nutrients and insect eggs in the trees are naturally removed, thus achieving the effect of preventing insects and corrosion; at the same time, sufficient water nourishment can weaken the biting force of the tree fibers, so that their resistance to change and stability become stronger.

解

Spliting

泡好的木头经过自然晾干后,手艺人将其锯断,得到大小合适的原木材料,并用弯形刮刀刮下含糖量高的树皮(包括维管束形成层和韧皮部),防止长虫。

After the soaked wood is dried naturally, it is sawn by craftsmen into log materials of the right size, and the bark with high sugar content (including the vascular bundle formation layer and bast) is scraped off with a curved scraper to prevent woodworm.

劈开木头-刮去树

去除树皮的木材用径切方式,从树材的根部往梢部方向顺木导管纹路进行分解:将整块木料垂直于年轮截面用刀锯劈出开口,用槌击打刀背,并打入楔子,将木头撑出裂缝;随着裂纹受力向深处自然扩展,木头也被劈撕为两半。将破开的半圆截面的木材用同样的方式继续劈撕、分解,得到一片一片的木板。

After removing the bark, the wood needs to be split by quarter sawing from the root to the tip of the tree in the direction of the wood conduit grain: first of all, perpendicular to the cross-section of the whole piece of wood, split a slit in the wood with a machete and whack the back of the machete with a mallet and drive in a wedge to hold the slit wide and create a crack. As the crack naturally expands under force, the wood is split in half. Next, continue splitting and tearing the cracked wood in the same way to get pieces of boards.

传统径切方法劈解木头 图示

用传统方法解木的过程

这种较为原始的、天然的解木方式,让木头应力分解而不破坏其纤维关系和导管结构,因此解出的木板纹路通直、性质稳定,不容易随着时间流逝而腐烂和解体。我们调研到中国西南山区的一种木楞民居所铺设的木瓦板便是使用这种传统的劈撕工艺制成,能够做到长年在屋顶经历风霜雨雪却不腐烂。

This primitive, natural way of splitting wood allows the wood to stress crack without destroying its fiber and conduit structure, so boards made from this method are straight-grained, stable, and not prone to rotting and disintegration over time. We found that in the mountainous regions of Southwest China, there is a kind of wooden shingle laid on wooden houses, which are made by this traditional splitting and tearing process, and can be on the roof for many years to experience the wind, rain and snow without rotting.

用传统方法解出的木材

解木所用的传统工具

Wood treatment: From timber to floor

初步解好的木料不能直接用于制材,而还需要经过粗平、细平到打磨、上漆等数道工序,才能将其加工成为地板。在工业机器尚未出现的时代,木匠都是使用传统的木工工具来进行木材的处理和制作,包括锛、鐁、刨等。

The initial split of the wood board can not be used directly for the production of flooring, but also need to be flatten、sanded、lacquered and other processes to become a floor.In the days before industrial machines, carpenters used traditional woodworking tools to work with wood, including adzes, planes, and so on.

锛

Adzing

用传统的劈撕方式制成的木板,表面粗砺不平,需要先进行初步加工。因木板尺寸较大,用刀削并不方便,便可以使用粗平工具“锛”锤劈木板,去除上面较大的结疤和起伏。在锤劈的过程中,木板上留下了一片一片的锛痕,形成特别的肌理。

The surface of boards made by traditional splitting and tearing is rough, and needs to be preliminarily processed first. Since the boards are large and not easy to cut with a knife, they can be hitted with an adze to remove the large knots and bumps. In the process of adzing the wood, the boards are left with adze marks, creating a special texture.

用“锛”初步处理木材的过程

鐁

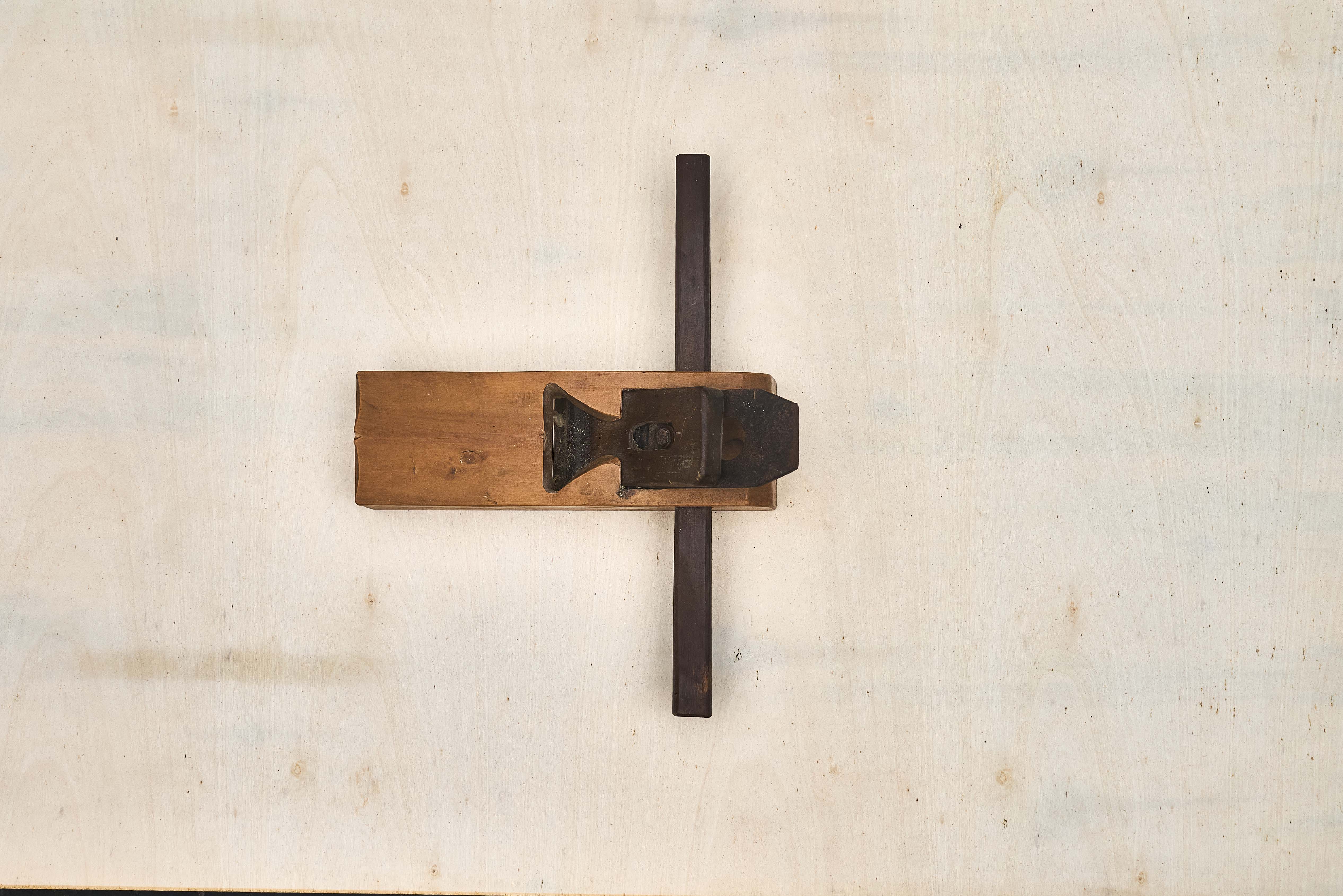

Scraping with Chinese spear plane

对于粗略处理后凹凸不平的木板,正好可以用到一种古老的细平工具“鐁”,进行更细致的处理。“鐁”是一种双面刃的平木工具,刀刃前端向上微微翘起。将刀刃用磨石打磨锋利后,一手握柄,一手扶住刀刃后端,在木板表面用侧刃向后削,让木板进一步变得平整,但仍然有长条状的削痕,削痕之间呈现出细细的楞起。

The roughly treated uneven board can be treated in more detail with an ancient woodworking tool called "Chinese spear plane". The Chinese spear plane is a double-edged scraping tool, with the front of the blade cocked slightly upwards. The carpenter first uses a whetstone to sharpen the blade, then holds the handle in one hand and the back end of the blade in the other, and scrapes backward with the side of the blade on the surface of the board, so that the board further becomes smooth, but there are still long scrape marks, and thin flutes between the marks.

用“鐁”进一步处理的过程

刨

Planing

“刨”也是一种传统的木工工具,可以去除木材的毛糙、锯痕等,让木头达到细平和净光的效果。在使用时可以手持平推式刨具,在木板上顺纹平推、刮削木板;过程中先进行粗刨、平整木板,后调整刀刃的角度和尺度,再进行细刨,让木板更加光平。木板在刨具的反复摩擦下受热并自然分泌油脂,逐步达到现代工业机器无法达到的平滑度。到这一步时,地板已经基本成型,表面平整光滑。

The plane is also a traditional woodworking tool that removes roughness and saw marks from wood board, leaving it fine and clean. When using a flush plane, you need to hold the planer on the board to scrape the board along the grain; the process starts with rough planing to flatten the board, then adjusting the angle and scale of the blade, and then fine planing to make the board more flat. The boards are heated by the repeated friction of the plane and naturally secrete oil, gradually achieving a smoothness that cannot be achieved by modern industrial machines. At this point, the floor has been basically molded, the surface is flat and smooth.

“刨”的过程

磨

Sanding

经过这些平木工序后的地板并不能直接上漆,还需要打磨得更加光滑。古代的匠人打磨木料时会使用一种带有毛刺的草——木贼。将晾干储存的木贼温水浸泡后,摊平且贴在小木块上,然后对木材表面进行反复摩擦,直至木板表面光净明亮。这种打磨方式天然环保,不会损伤木材。

After all these processes, the floor can not be painted directly, but also needs to be sanded to a smoother finish. Ancient craftsmen used a burly grass, known as horsetail grass, to polish wood. First soak the horsetail grass in warm water, flatten it and stick it on a small wooden square and use it to rub the surface of the board repeatedly until it is clean and shiny.This type of sanding is natural, environmentally friendly and does not damage the wood.

木贼打磨的过程

漆

Lacquering

地板制作的最后一道工序是擦漆。我们使用了中国传统的髹漆工艺:用从漆树提取的天然大漆涂料对打磨好的地板进行涂装。首次擦漆后,将地板送入特定湿度和温度的阴房进行荫干;待漆膜干透后,用树叶沾水打磨表面,再进行第二次擦涂。反复数次之后,才能完成上漆。至此,一块传统方法制作的木地板就完成了。

The last step in the process of making a floor is lacquering. We use the traditional Chinese process of lacquering, which is the application of natural lacquer extracted from the lacquer tree to the sanded floor. After the first lacquer application, the floor is allowed to shaded-dry in a shaded room at a specific humidity and temperature; once the lacquer is dry, the surface of the floor is rubbed with leaves moistened with water, and then a second lacquer is applied. After this step has been repeated several times, the lacquering process is complete. At this point, a wooden floor made by traditional methods is complete.

上漆-树叶打磨-再次上漆

从材到板的处理所用的传统工具

Reflection, Interpretation and perpetuation

如今,全球森林资源有限,环保理念和地暖的普及,使得原木地板已经无法满足当下要求。同时,随着科技发展和工具革新,传统的木地板制作方法被高效的机器制作方式所代替。不可否认,工业化的高效法则的确让我们的生活变得更方便快捷,而基于传统工艺的木构建筑或许远远没有现在那么快速能够建成,但是它却比现在的房子更经久耐用、历经千年不腐烂。这是值得我们思考的:一块好的原木木头用上千年,或用几十年、上百年就得更换一次,究竟哪种方式才更环保?

Nowadays, the global forest resources are limited, the environmental protection concept and the popularity of underfloor heating make the original wood floor can no longer meet the current use requirements. At the same time, with the development of technology and the innovation of tools, the traditional method of wood flooring production is replaced by efficient machine production methods. Undeniably, efficient industrialized production does make our lives easier and faster, and based on the traditional craft of wood construction may be far from now so quickly can be built, but it is more durable than the current house, can last for thousands of years without rotting. This is worth thinking about: an original wood stuff can be used for thousands of years, or other wood products with a few decades, hundreds of years will have to be replaced once, which way is more environmentally friendly?

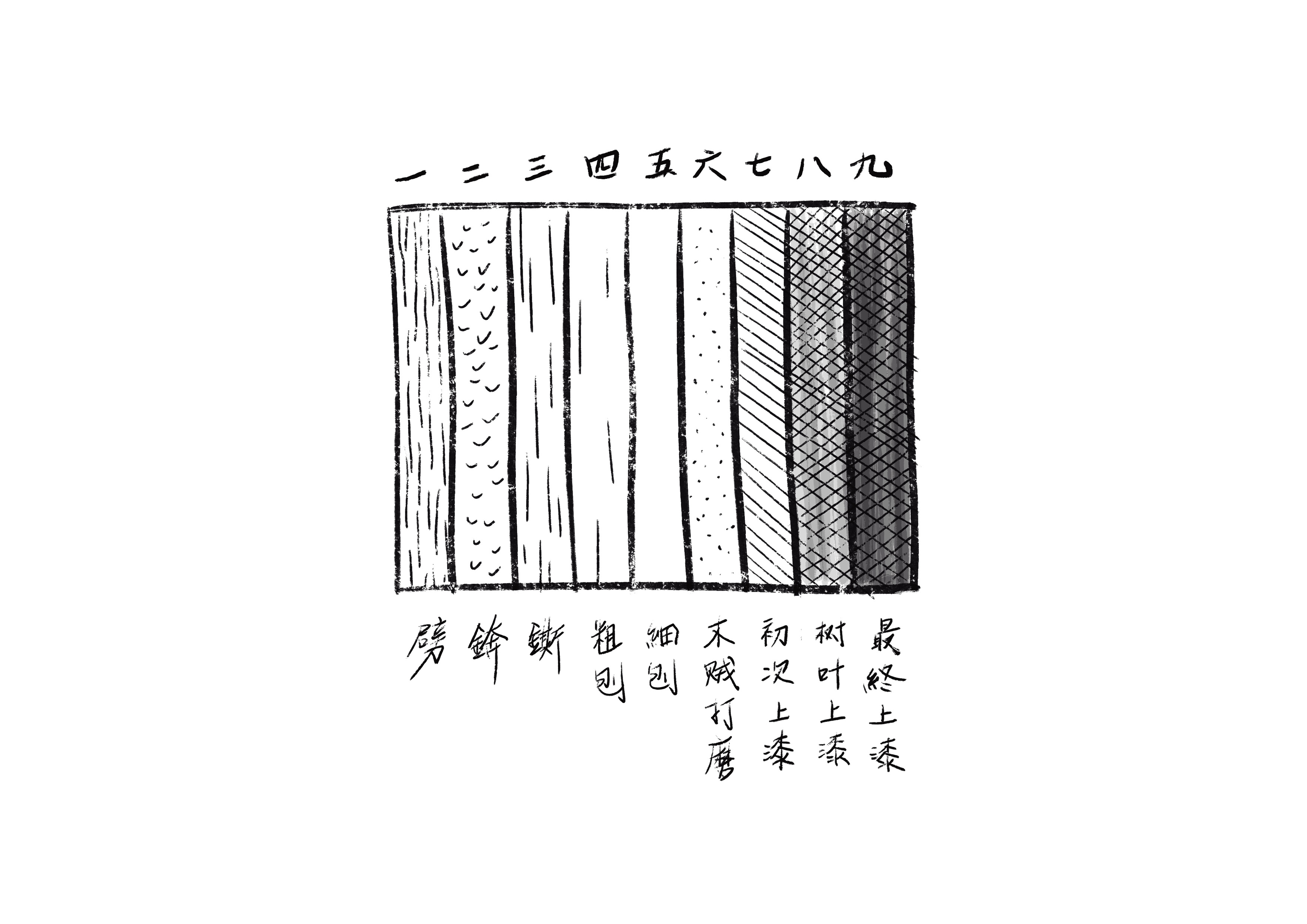

带着这样的疑问,我们寻回这种古老的手工艺,与范建军合作,将这次的研究成果用一套木地板作品呈现:九块木地板分别展现从劈解到上漆的九道工序。相邻的地板之间设置了古法榫卯结构的凹槽,将九块地板连接起来。

With this in mind, we sought to trace this ancient craft and collaborated with Fan Jianjun to present the results of our research as a work consisting of nine wooden floors, each showing the nine steps of the process from splitting to lacquering, with grooves in the form of ancient mortise and tenon joints between adjacent floors to serve as connections.

传统方法解木的九个步骤

传统方法解木的九个步骤

通过这一作品,我们试图回归木材料本身,为木材制作提供另一种被大家遗忘的可能性。这种传统的方式不仅可以用于制作木地板,也可以制作椅子、桌子等。这是对遵循自然的传统木工艺的具象再现,也是对一棵树的生命力的转化和延续。

With this work, we try to bring the focus back to the wood material itself, offering a forgotten possibility for the making of wood. This traditional method can be used to make not only wooden floors, but also chairs and tables.This is a figurative reproduction of traditional wood craftsmanship that follows the laws of nature, as well as an interpretation and perpetuation of the life of a tree.

图片&视频|Vincent Kuan

Picture&Video | Vincent Kuan

特别感谢|范建军、黄大拿

Acknowledgement | Fan Jianjun Huang Dana